History

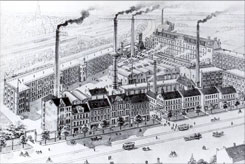

140 years of Continental starting at 1871 - 1900 Spirit Of Optimism

In 1871, Continental-Caoutchouc- and Gutta-Percha Compagnie is founded in Hanover as a joint stock company. Manufacturing at the main factory in Vahrenwalder Street includes soft rubber products, rubberized fabrics, solid tires for carriages and bicycles.

1882, the rampant horse is adapted as a trademark and in 1892, Continental is the first German company to manufacture pneumatic tires for bicycles.

In 1898, the production of automobile pneumatic tires without tread pattern starts in Hanover-Vahrenwald and in 1900, the first German airship LZ 1 uses Continental's balloon material to seal the gas bags

1901 - 1930 Inventive Talent

| 1901 | The first Daimler-produced car with the Mercedes name, achieves a sensational victory on Continental pneumatic tires in the Nice-Salon-Nice car race. |

| 1904 | Continental presents the world's first automobile tire with a patterned tread. |

| 1905 | Continental produces anti-skid tires with rivets, the forerunner of specialist studded tires. |

| 1907 | The first edition of Continental's Road Atlas for motorists and motorcyclists is published. |

| 1908 | Continental invents the detachable rim for sedans - a remarkable innovation that saved time and effort when changing a tire. |

| 1909 | Specimens of synthetic rubber developed at the Bayer laboratories are successfully vulcanized at Continental and processed to make the first test tires. Louis Blériot, the pioneer aviator, writes history with the first flight across the English Channel. Continental Aeroplan material covers the fuselage and wings of his plane. |

| 1912 | Construction of an administration building designed by architect Peter Behrens begins in Vahrenwalder Street. in 1986, this building is bought by the Hanover City Council to house a technology center. |

| 1914 | Triple victory for Daimler cars fitted with Continental tires at the French Grand Prix. |

| 1921 | The company's 50th anniversary sees Continental as the first German company to bring a cord tire onto the market. The earlier stiff linen, square-woven fabric, is now replaced by the more pliable, cord fiber fabric. The first giant pneumatic tires are made by Continental and start to replace the solid tires used by commercial vehicles until that time. |

| 1926 | Carbon black is used as a reinforcing filter to give the tire more resistance to wear and ageing, as well as its characteristic color. |

| 1928/29 | Merger with major companies of the German rubber industry to form Continental Gummi-Werke AG. Takeover of plants in Hanover-Limmer and Korbach/Hesse. |

1931 - 1960 Motor Racing Success

| 1932 | Continental markets a rubber-metal bonding process with the registered trade name of Continental Schwingmetall. It is used to isolate vibrations and noise when supporting motors. |

| 1935-40 | Unbroken run of racing success with Continental racing tires fitted to Mercedes and Auto-Union cars. Four consecutive wins in the German Grand Prix, four successes in the North African Tripoli race, three in Italy and numerous speed records help racing drivers like Carraciola, Rosemeyer and Stuck to achieve international fame. |

| 1936 | Synthetic rubber is introduced into the tire manufacturing process. |

| 1938 | Foundation stone is laid for the tire plant in Stöcken, Hanover. |

| 1945 | Heavy bomb damage to the plants in Hanover-Vahrenwald and Korbach. The British military government grants permission as early as June, 1945 for the Hanover factories to resume production. |

| 1951 | Production of steel cable conveyor belt starts. |

| 1952 | Continental adds M+S tires for winter driving to its range of conventional tires. |

| 1951-55 | In close collaboration with Daimler-Benz and Porsche, Continental repeats its pre-war successes on the track. Racing in cars fitted with Continental tires, drivers like Karl Kling, Stirling Moss and Juan Manuel Fangio win the 1952 Carrera Panamericana and the French, British, Dutch and Italian Grand Prix. |

| 1955 | At the beginning of the year, Continental is the first German company to start manufacturing tubeless tires. Continental is also the first company to develop air springs for trucks and buses. |

| 1960 | Mass production of radial tires begins. |

1961 - 1990 Internationalisation

| 1961 | Completion of the plant in Dannenberg, Germany. Initial production comprises plastic components for the automotive industry. |

| 1964 | Construction of a tire plant in Sarreguemines, France. A factory for industrial products is built in Northeim, Germany. |

| 1967 | Opening of the testing facility on the edge of the Lüneburg Heath. In 1994/95, the facility more than doubles in size to enable the construction of new tracks, including a 3.8 kilometer handling course for high-performance cars. In 2001, a 3.7 kilometer track for noise assessment is opened. |

| 1971 | Europe's largest hose manufacturing facilities are set up at the Korbach plant. The entire hose production is transferred from Hanover to Korbach. |

| 1972 | Continental launches the studless ContiContact winter tire. |

| 1974 | Continental is the first manufacturer to supply the European automotive industry with extrusion-blow-molded polyurethane gaiters. |

| 1976 | In Northeim, one of Europe's largest conveyor belt production lines comes on stream. |

| 1978 | In close collaboration with Daimler-Benz and Porsche, Continental repeats its pre-war successes on the track. Racing in cars fitted with Continental tires, drivers like Karl Kling, Stirling Moss and Juan Manuel Fangio win the 1952 Carrera Panamericana and the French, British, Dutch and Italian Grand Prix. |

| 1979 | Takeover of the European tire operations of American tire company Uniroyal, Inc. This gives Continental a much broader customer base in the European market. |

| 1983 | Continental hydromounts - special bearing elements used in engines for damping vibrations and noise - are mass-produced for the automotive industry. |

| 1985 | Takeover of the tire operations of the Austrian company Semperit. |

| 1987 | Acquisition of the North American tire manufacturer General Tire, Inc. The company has been operating under the name of Continental Tire North America, Inc. since 2001. |

| 1989/90 | A joint venture is set up together with the Portuguese company Mabor for the production of tires in Lousado. 1993 sees the complete takover of their tire activities and of a factory producing textile cord. |

1991 - 2010 Automotive Supplier

| 1991 | The industrial products operations are reorganzied under the ContiTech umbrella brand. With its ContiEcoContact tire, Continental is the first manufacturer to launch an environmentally-friendly passenger tire. |

| 1993 | The majority holding in the Czech company Barum comprises a passenger and commercial vehicle tire plant in Otrokovice as well as a dealer organization with about 50 outlets. Continental currently has approximately 2000 tire retailers and franchises in 15 European countries, including various retail organizations such as Vergölst. Benecke-Kaliko AG is integrated into the ContiTech division. Key products are leatherette and sheeting. |

| 1994 | Joint venture between ContiTech and the Slovakian company Vegum for the production of rubber extrusions for the European automotive industry. In 1996, the agreement is extended to include moulded products. |

| 1995 | The Continental Automotive Systems division is established to intensify the systems business with the automotive industry. ContiTech takes over the power transmission products activities of TBA Belting Ltd. |

| 1997 | Continental presents ISAD (Integrated Starter Alternator Damper) technology, for which it receives the German Industry Innovation Award. ISAD is a key technology that reduces fuel consumption and replaces the vehicle's starter and generator with one single unit. |

| 1998 | Acquisition of a US company's Automotive Brake and Chassis unit, the core of which is Alfred Teves GmbH in Frankfurt. Continental Teves and its worldwide operations are integrated into the Automotive Systems division. |

| 1998/99 | Continental reinforces its position as a global tire manufacturer by adding sites in Argentina, Mexico, South Africa and Slovakia. Further steps in the process of globalizing ContiTech's operations are taken in Brasil, Chile, Mexico (photo) and Hungary. |

| 2000 | A new plant for the manufacture of passenger tires is openend in Timisoara, Romania (photo). Continental and Nisshinbo set up a new joint venture (Continental Teves Corporation) in the field of brake and chassis systems for the Japanese and Korean markets. |

| 2001 | Majority holdings are purchased in two Japanese companies manufacturing brake actuation components and disk brakes. ContiTech acquires a 51% stake in a Chinese company making air-conditioning and power-steering hose lines. Continental reinforces its activities within the growing automotive electronics market by acquiring electronics specialist Temic (photo: Nuremberg plant). The company is integrated into the Automotive Systems division. |

| 2002 | Continental and Bridgestone join forces in the developement of run-flat tires. The objective is to create a worldwide standard for run-flat systems installed on conventional rims. Inauguration of ContiTech's new plant for the production of power transmission systems in Romania and of a factory in Turkey providing the division with extra manufacturing capacity for air spring systems. To increase tire activities with Japanese carmakers, Continental and Yokohama establish a 50/50 joint venture. |

| 2003 | Continental strengthens its position in the ASEAN region and Australia by establishing a joint venture together with Malaysian conglomerate Sime Darby Berhad. The company, operating under the name of Continental Sime Tyre Sdn. Bhd., has two tire plants in Malaysia. ContiTech sets up a joint venture for the production of air spring bellows in Korea. |

| 2003 | Unveiling the ContiSportContact 2 Vmax, the world's first road tire approved for speeds up to 360 km/h (224 mph). |

| 2004 | Continental expands its production base in Romania by opening up a plant making assemblies for automotive electronics – with an on-site R&D center – in Sibiu, as well as a manufacturing facility for air-conditioning lines in Timisoara. Continental acquires the wheel sensors business of a Japanese company with manufacturing operations in China. |

| 2004 | Inauguration of a new plant in Mexico for the production of brake components. Takeover of Phoenix AG. With the merger of ContiTech and , the world’s largest specialist for rubber and plastics technology evolves. |

| 2005 | Cooperation with ZF Friedrichshafen for the joint development and marketing of hybrid vehicle technology. |

| 2006 | Production of brake calipers commences at the new plant in Zvolen, Slovakia, and of passenger-, light truck- and commercial vehicle tires in Camacari, Brazil. ContiTech acquires a Danish manufacturer of power transmission belts with production facilities in Denmark, China, Korea and India. Continental acquires the automotive electronics business of Motorola, Inc. The new unit is integrated into the Automotive Systems division. It includes Motorola’s operations in the growing fields of controls, sensors, interior electronics and telematics, with plants in North America, Japan, China, Mexico, France, UK and Germany. |

| 2007 | Continental acquires a majority interest in the Slovak company Continental Matador Rubber s.r.o. and expands its position for the Tires and ContiTech divisions in Central and Eastern Europe. Continental acquires Siemens VDO Automotive AG and becomes one of the top five suppliers in the automotive industry worldwide, at the same time boosting its market position in Europe, North America and Asia. |

| 2008 | Production of lithium ion batteries for use in vehicles with hybrid drives begins in the Nuremberg plant. Schaeffler KG becomes the major shareholder of Continental AG following the conclusion of the takeover offer published in the summer of 2008. |

| 2009 | The new Asian headquarters and a research and development center is opened in Shanghai. The center represents another major milestone for the company’s growth in China and Asia. |

| 2010 | The ContiSportContact™ 5 P is launched onto the market. This new, high-performance summer tire is specifically designed for sports cars and tuned, high-performance vehicles. |

2011 – Today: The Future in Motion

| 2012 | Start of extensive automated-driving tests in the U.S. state of Nevada. A highly automated Continental test vehicle has covered 15,000 miles on public roads without any accidents. |

| 2017 | For the first time, the company employs more than 235,000 employees all over the world. Annual sales amount to €44 billion. |

| 2017 | Continental has built a test vehicle to enable driverless mobility, especially in cities. Called a CUbE (Continental Urban Mobility Experience), this vehicle is being trialled at the Frankfurt site. |

| 2018 | Opening of the research and experimental laboratory “Taraxagum Lab Anklam” in Anklam, Mecklenburg-Vorpommern, Germany. It provides a base for research into the cultivation and processing of Russian dandelion as an alternative source of raw material to the rubber tree. |

| 2020 | Through its architecture, the new Continental headquarters – which are to be inaugurated to mark the company's 150-year anniversary – symbolize and promote the culture of innovation and interconnectivity at Continental. The new campus meets the demand for agile, flexible and interconnected collaboration throughout the entire organization, as is already common practice at Continental worldwide. |